Return on investment in Maintenance

Have you ever stopped to think about how much you would give to reduce your company’s costs by adopting efficient maintenance management?

Return on investment in Maintenance

Have you ever stopped to think about how much you would give to reduce your company’s costs by adopting efficient maintenance management?

Return on Investment - ROI

Engeman® provides an excellent Return on Investment improving produce quality.

Companies depend on high importance equipment for production processes, it’s up to maintenance to keep everything working properly and reduce the unexpected breaks risks and, consequently, delays in production.

With a maintenance system, the entire company management improves, as it provides efficiency in the processes, increased productivity and maintenance costs optimization.

Download the spreadsheet, enter your data and calculate your ROI with Engeman®

How do you use the ROI spreadsheet?

We help our customers to calculate the cost reduction potential that can be achieved in the company through the adoption of techniques focused on maintenance engineering concepts through our tool.

To calculate, let’s take as an example a company that performs:

And consider that best practices define as a goal:

We enter this data in the Return on Investment spreadsheet and that's it!

RESULTADO:

Maintenance Cost Reduction Potential.

*Method based on statistics published in the National Manufacturing Week Conference World Class Maintenance 1998 – Chicago – USA.

Now it’s your turn! Just download the spreadsheet and enter your data.

Now it’s your turn! Just download the spreadsheet and enter your data.

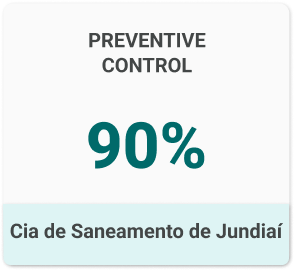

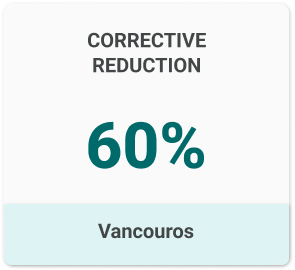

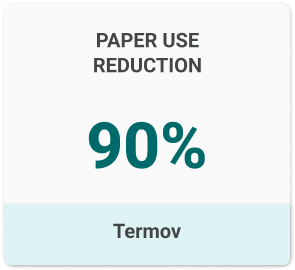

Engeman® customers prove the return in reliability of their equipment by using our solution!

Sign up for our newsletter

and receive free content for your maintenance!

An intelligent maintenance provides more efficiency in processes, increased productivity and, consequently, faster return on investment!

An intelligent maintenance provides more efficiency in processes, increased productivity and, consequently, faster return on investment!